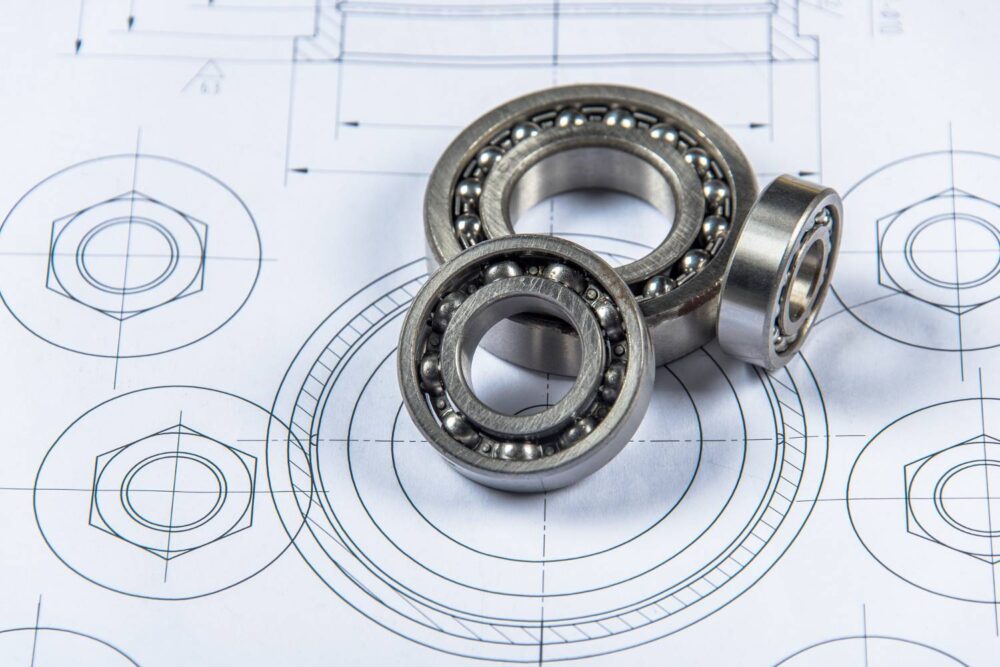

Ball Bearing vs Roller Bearing: Key Differences

When considering ball bearings for your applications, the choice between ball bearings and roller bearings is crucial and should be guided by the specific load requirements of each situation. Both types have distinct characteristics that make them more suitable for different operating conditions. Ball bearings are often used in applications that require less friction and high-speed movement, while roller bearings are ideal for supporting heavier and more extreme loads.

Understanding these fundamental differences not only optimizes equipment performance but also extends durability, directly reflecting in efficiency and reducing maintenance and replacement costs. The right choice can make all the difference in the productivity and longevity of mechanical systems. Therefore, it is essential to carefully analyze the specific needs of each application before deciding between these two types of bearings.

When considering ball bearings for your applications, the choice between ball bearings and roller bearings is crucial and should be guided by the specific load requirements of each situation. Both types have distinct characteristics that make them more suitable for different operating conditions. Ball bearings are often used in applications that require less friction and high-speed movement, while roller bearings are ideal for supporting heavier and more extreme loads.

Understanding these fundamental differences not only optimizes equipment performance but also extends durability, directly reflecting in efficiency and reducing maintenance and replacement costs. The right choice can make all the difference in the productivity and longevity of mechanical systems. Therefore, it is essential to carefully analyze the specific needs of each application before deciding between these two types of bearings.

Structure and Design

Ball Bearings:

-

Characterized by small balls positioned between two races.

-

Provide significant friction reduction, smooth and quiet operation.

-

Can support moderate radial and axial loads.

-

Ideal for applications requiring precision and low resistance.

Roller Bearings:

-

Use cylinders instead of balls.

-

Larger contact area allows support for much heavier radial and axial loads.

-

Effective in extreme load conditions, common in heavy industries.

The choice must be based on a careful evaluation of the load requirements. Selecting the wrong type can lead to premature wear and extra maintenance costs, while the right bearing ensures productivity and efficiency.

Load Capacity

-

Ball Bearings: Best for lighter loads and high-speed requirements. They reduce friction during operation, ensuring smooth performance in precision machinery, power tools, and household appliances.

-

Roller Bearings: Designed for higher loads, distributing pressure across a larger surface area. Widely used in heavy industrial machinery and automotive vehicles, where impact forces and axial loads are common.

By understanding these differences, engineers can ensure optimal performance and longer machine life, reducing overall operating costs.

Common Applications

Ball Bearings in High-Speed Operations

-

Used in electric motors, where high-speed operation is required.

-

Minimize friction, allow parts to rotate freely at elevated speeds, and handle moderate axial and radial loads.

Roller Bearings in Vehicles and Industrial Machinery

-

Applied in truck axles, transmissions, and heavy machinery.

-

Cylindrical or tapered rollers distribute loads evenly, ensuring durability and stability under heavy pressure.

Maintenance and Durability

-

Ball Bearings: Require less maintenance due to their low-friction design. They can run efficiently for longer periods without frequent servicing, reducing downtime and operational costs.

-

Roller Bearings: More durable under heavy loads but may demand more frequent lubrication. Their larger contact surfaces increase load capacity but also require consistent maintenance to prevent wear.

A preventive maintenance strategy—regular lubrication, inspections, and monitoring—can significantly extend the life of both bearing types.

Efficiency and Performance

-

Efficiency of Ball Bearings: Recognized for minimizing rolling resistance, consuming less energy during operation. They are ideal where energy savings and high-speed performance are priorities.

-

Performance of Roller Bearings: Known for high load capacity and rigidity, critical in heavy-duty applications where stability and strength are essential.

Conclusion

Bearings are essential mechanical components used in a wide range of equipment to reduce friction between moving surfaces. Among the most common are ball bearings and roller bearings.

-

Ball Bearings: Support moderate radial and axial loads, ideal for high-speed, low-friction applications such as fans and electric motors.

-

Roller Bearings: Handle heavier radial loads thanks to their larger contact area, making them more effective in industrial equipment, conveyors, and cranes.

Other key considerations include rigidity, noise, and maintenance:

-

Ball bearings generally provide smoother, quieter operation with less maintenance.

-

Roller bearings offer more rigidity and higher load capacity but may require more frequent servicing.

The choice between ball and roller bearings must always be based on application-specific requirements and load demands. Understanding these differences ensures better performance, increased durability, and higher efficiency in mechanical systems.