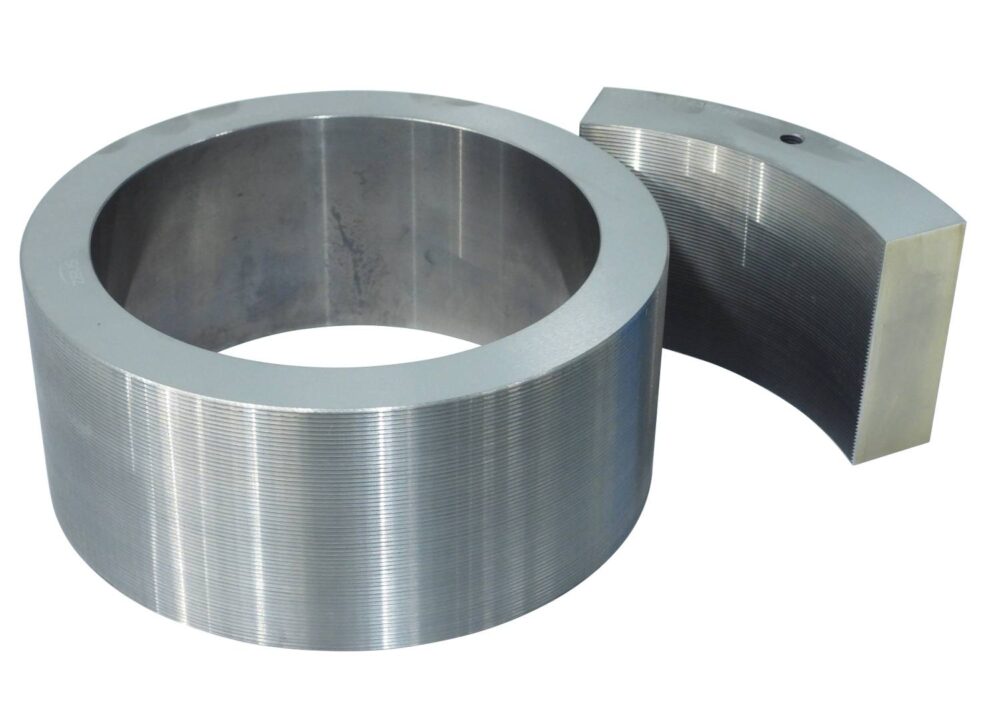

Tungsten Carbide Dies and Tools Grinding

The precision grinding of tungsten carbide dies represents a critical service in modern nail manufacturing. Our company specializes in TC Dies Grinding Service using state-of-the-art Korean grinding machines equipped with micro-feed systems and sophisticated cooling mechanisms. The grinding process of each tool can take up to 48 hours, utilizing specialized cooling oil to ensure maximum precision and quality. These tools are essential components of thread rollers, machines that create grooves in nail shanks to enhance their retention capability in materials.

Our advanced grinding technology allows for exceptional accuracy in processing tungsten carbide, a material chosen for its superior hardness and durability. The process involves continuous monitoring of all parameters, precise temperature control, and micro-adjustment capabilities. Our facility in the Czech Republic maintains the highest standards of precision grinding, serving clients who require top-quality tool maintenance and restoration. The unique properties of tungsten carbide necessitate specific grinding parameters, expert knowledge, and specialized equipment, all of which we provide through our comprehensive grinding service.

Tungsten Carbide Tool Grinding

The ZURO TL Tungsten Carbide Tools require specialized grinding approaches and maintenance procedures. Our Tungsten Carbide Tool Grinding services employ cutting-edge technology and methodologies that ensure optimal results. Each tool undergoes thorough initial inspection, followed by a precise grinding process with continuous monitoring of all parameters. The Zeus Techno Grinding Service guarantees the highest processing quality thanks to advanced Korean grinding machines and experienced technical personnel. Our grinding process incorporates multiple stages:

Diagnostic Phase: Detailed tool condition analysis and geometric parameter measurement

Preparation Phase: Machine setup according to specific requirements and cooling system preparation

Grinding Phase: Controlled grinding with micro-feed capability and continuous temperature monitoring

Quality Control: Ongoing measurements and final inspection

This comprehensive approach ensures that each tool meets exact specifications and maintains optimal performance characteristics.

Tungsten Carbide Tool Sharpening

Tungsten carbide tool sharpening requires exceptional precision and specialized equipment. Our service includes complete tool diagnostics, precise sharpening, and thorough quality control procedures. We utilize advanced measuring systems to ensure accurate geometric parameters throughout the sharpening process. The sharpening procedure involves:

Initial assessment of tool condition

Custom grinding program development

Precision sharpening with continuous monitoring

Final quality inspection and documentation

Our advanced cooling systems prevent thermal damage during the sharpening process, while maintaining the tool’s structural integrity. We offer expert consultation on tool maintenance and optimal utilization to extend service life and maintain peak performance.

Nail Making Tool Grinding

We specialize in grinding tools for thread rollers, which are crucial for quality nail production. These Nail Making Tools must meet the highest standards of precision and durability, as they create specific grooves on nail shanks that ensure better material retention. Our Korean grinding machines with micro-feed capability achieve the required precision through:

Specialized fixtures and positioning systems

Advanced cooling technology

Precise parameter control

Continuous quality monitoring

The grinding process for nail making tools requires particular attention to detail, as these tools directly impact the final product quality. Our expertise in this specific area allows us to maintain and restore these specialized tools to their optimal working condition.

We offer comprehensive services in tungsten carbide tool grinding, specializing in tools for thread rollers. Our services include both grinding services and sales of thread rollers and related tools. With modern equipment and an experienced team, we guarantee the highest processing quality.

For more information about our services and products, please visit https://www.zeus-techno.com/news/tungsten-carbide-dies-grinding/